【Product】Introducing DediProg PCB/R Socket

2024-10-09

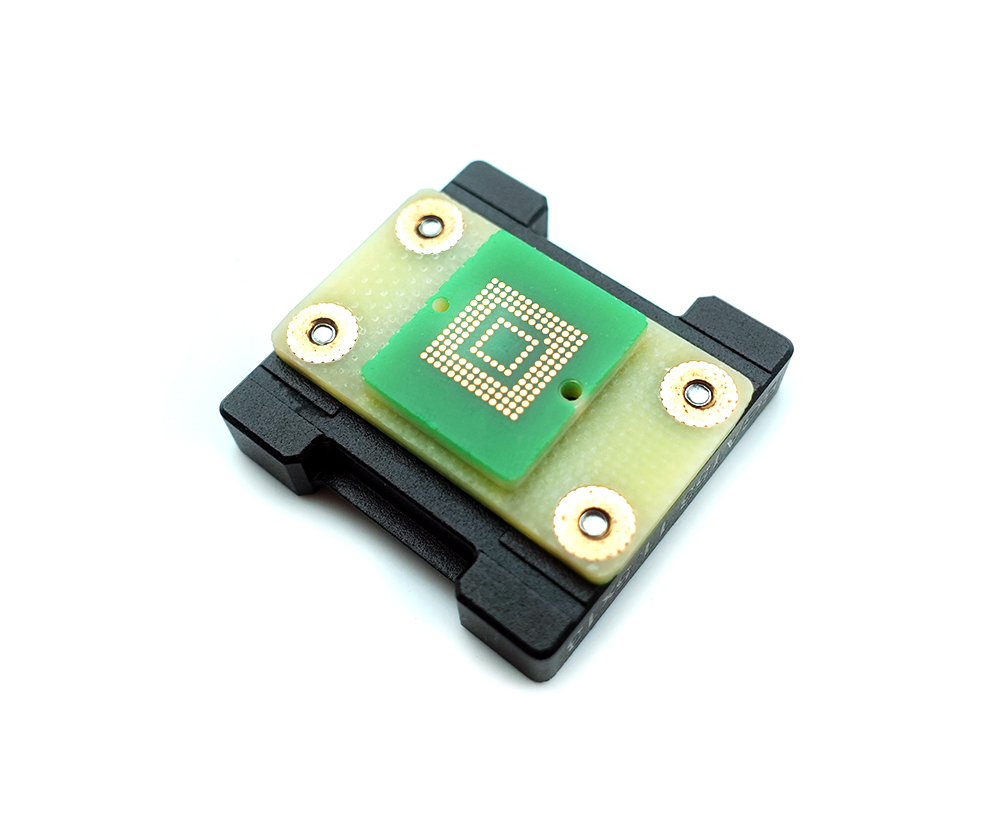

Introducing DediProg PCB/R Socket

Enhancing IC Testing Efficiency and Minimizing Component Damage Risks

When only a single PCB is available for testing multiple ICs, traditional methods of soldering, testing, and removing ICs are time-consuming and risk damage. To solve this, DediProg has developed the PCB/R Socket testing fixture with Pressure Conductive Silicone Rubber (PCR) for a more stable and efficient solution.

|

Challenges of Traditional IC Testing

- Risk of Board Damage

Repeatedly soldering and desoldering ICs can cause damage to the copper traces and solder joints on the PCB.

- Risk of IC Damage

Frequent assembly and disassembly may lead to IC damage or pin deformation, affecting component reuse.

- Time-Consuming

The soldering and desoldering process is cumbersome, which can hinder work efficiency.

- Operational Difficulty

The process requires specialized skills and equipment, making it challenging for non-professionals to handle.

PCB/R Socket IC Testing Solution

The solution streamlines the process by eliminating the need for repeated soldering, enhancing efficiency, and reducing the risk of component damage.

- Reduces Testing Time and Labor Requirements

The PCB/R Socket can be soldered directly onto the PCB, allowing ICs to be inserted and replaced without repeated soldering. This shortens test cycles and reduces the need for skilled manual handling.

- Prevents Damage to ICs and PCBs

The PCB/R Socket eliminates the need for repeated soldering of ICs, reducing the risk of damage to both the PCB and ICs. DediProg’s self-developed PCR material also prevents indentation marks on ICs.

- Suitable for Populated Boards and Varied Applications

With an adapter board sized to match the IC and a built-in 1.5mm component clearance, the PCB/R Socket is ideal for use on fully assembled PCBs, including densely populated product motherboards.

- Enhances Signal Integrity and Maintenance Efficiency

DediProg’s self-developed PCR provides low contact resistance, high signal integrity, and convenient replacement—ensuring reliable performance over repeated testing cycles.

Here's how to use the PCB/R Socket for efficient IC testing:

- Solder the PCB adapter onto the PCB.

- Secure the mounting plate onto the adapter.

- Insert the IC into the socket.

- Close the lid to initiate testing.

- To replace the IC, remove it from the socket and insert a new one.

Advantages of PCB/R Socket with Self-Developed PCR

DediProg's PCB/R Socket features our self-developed PCR, which provides several key advantages:

- High Transmission Rate and Low Resistance

Ensures stable and rapid signal transmission, particularly suitable for high-precision testing environments.

- Impression-Free Design

The PCR prevents any surface impressions on the IC, further safeguarding the integrity and functionality of the components.

- Easy Material Replacement

The design of the PCR material allows for straightforward and simple replacement of consumables, extending product lifespan and reducing maintenance costs.

Flexible Design to Meet Diverse Needs

DediProg provides standard socket types along with various PCB adapter sizes, and we offer fully customized designs according to customer requirements. When testing space permits, the socket can be further designed with real-time signal transfer points, allowing engineers to conduct signal measurements anytime, enhancing testing accuracy and efficiency.

E-mail: sales@dediprog.com