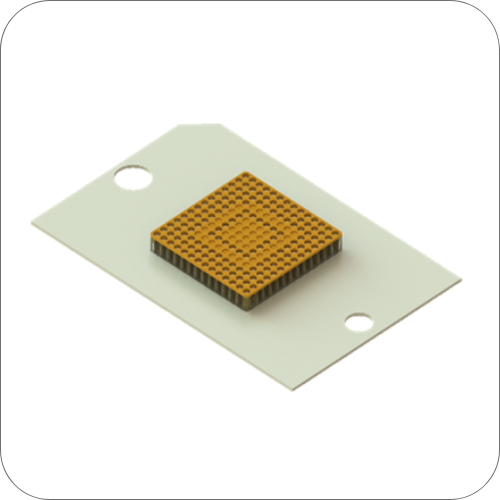

IC Test Socket

Stable transmission, durability as always.

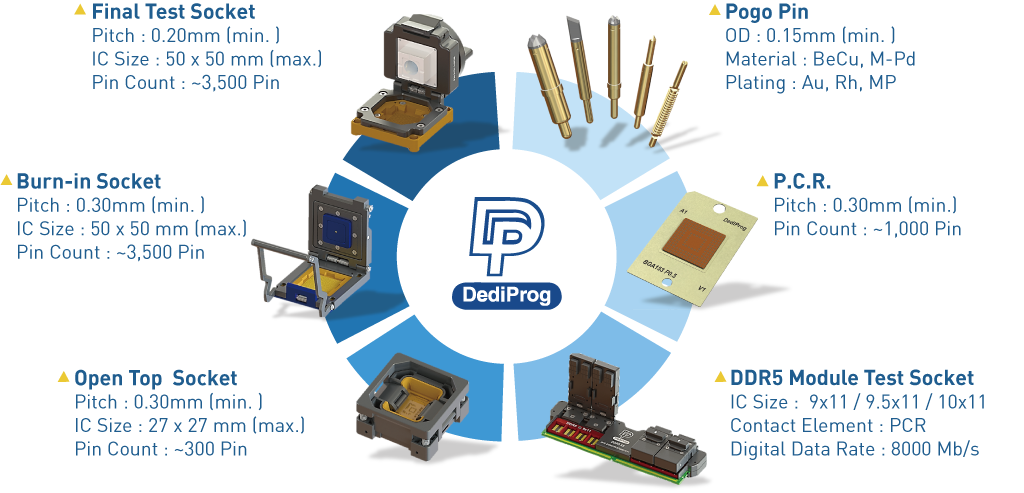

The IC Test Sockets are widely used for back-end testing of chips finalizing. It can work under strict testing conditions and transmit signals with chips without soldering them onto a PCB, which helps the engineers quickly and accurately implement the inspection procedure.

DediProg's IC test socket supports burn-in tests, packaging tests, and final tests.

|

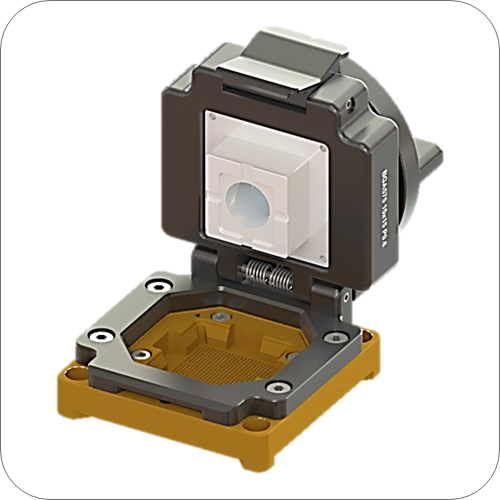

| Final Test Socket

| |

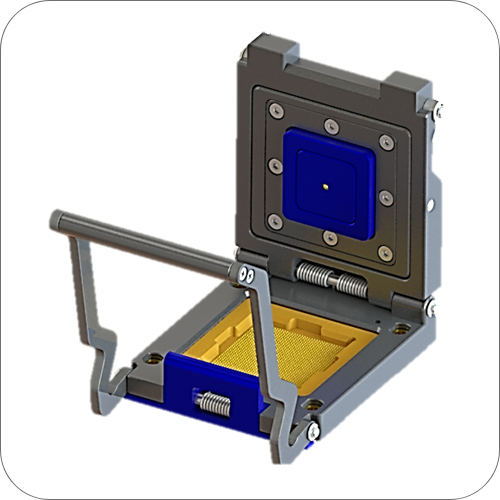

| Burn-in Socket

| |

| Open Top Socket

| |

| DDR5/DDR4 Module Test Socket→ Discover More on DDR5 Module Test Socket | |

| Pogo PinWe focus on the R&D of materials and manufacturing processes for Pogo Pins. To meet strict testing requirements, we offer corresponding material technologies that reduce cleaning frequency and improve testing yield. We accept custom orders for various probe specifications, including shape, material, and elasticity. We can also provide S-parameter simulation reports. | |

| Pressure Conductive Silicone Rubber, P.C.RHigh-speed transmission, low resistance, and no damage to solder balls. The special molding technique ensures that conductive particles are tightly aligned, resulting in excellent performance in both contact and resistance. → Discover More on Pressure Conductive Silicone Rubber, P.C.R |

|  |  | ||

One-stop Service |

| Fast Lead Time |

| RD Capabilities |

We design and produce everything independently, ensuring stable and safe quality control. | We can ship quickly within 2-4 weeks of placing an order. | Our R&D team is experienced in discovering and developing. |