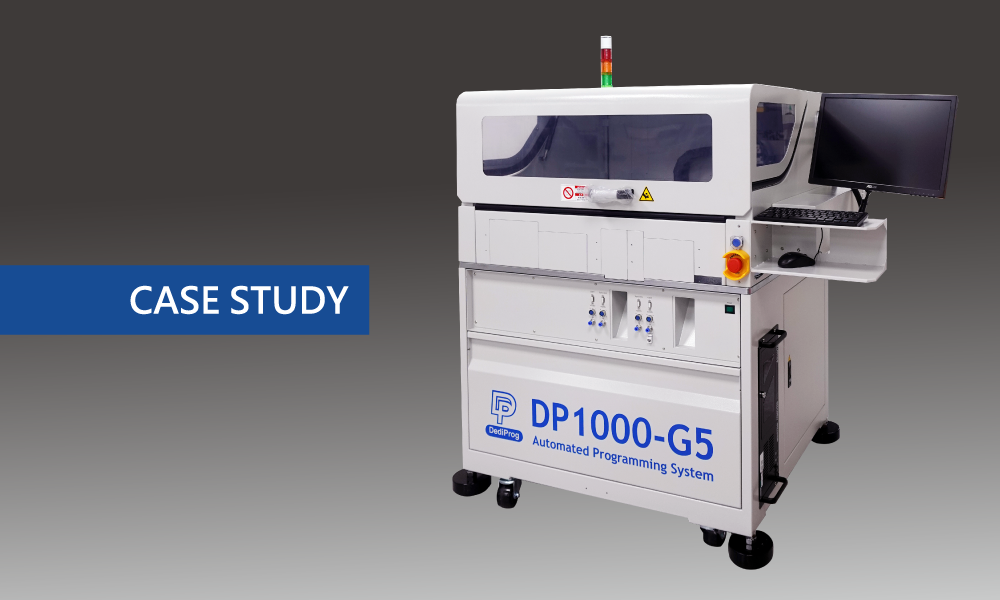

【Case Study】Streamlining IC Programming Efficiency with DP1000 Series

2023-12-30

Streamlining IC Programming Efficiency: A DediProg Case Study

In the dynamic realm of Electronics Manufacturing Services (EMS), precision, speed, and cost-effectiveness are critical factors that determine a company's success. DediProg, a renowned leader in IC programming solutions, has been pivotal in transforming the IC programming process for one of its esteemed customers. In this case study, we'll delve into the journey of ○○○, a real-world client who partnered with DediProg to enhance their IC programming operations.

Customer Profile: ○○○ (Customer Name withhold)

○○○ is a well-established electronics manufacturer with a strong reputation for producing cutting-edge electronics, including telecommunication, automotive, and wearable devices. As consumer demands evolved, ○○○ faced increasing pressure to deliver products faster, with greater precision, and at competitive prices.

The Challenge: Meeting Industry Demands

○○○ found themselves at a crossroads. The rapidly evolving consumer electronics industry demanded shorter production cycles and higher product quality, leaving no room for error. The original in-house manual programming, which they had relied on for years, was no longer sufficient to meet these demands. The challenges they faced included:

•Slower Production: The manual programming system was unable to keep pace with the high production volumes required to meet market demand.

•Quality Concerns: Human error in programming led to occasional defects and inconsistency in product quality.

•Labor Costs: A large workforce was needed for manual programming, resulting in soaring labor costs.

The Solution: Partnering with DediProg

Recognizing the need for a transformative solution, ○○○ turned to DediProg. Together, we identified the challenges and set out to implement DediProg auto handler DP1000 Series for device programming process at SMT line (Surface Mount Technology line). Here's how the solution unfolded:

High Throughput: Meeting Market Demand

○○○ was impressed by the exceptional throughput of DediProg's auto handlers. The DP1000 Series machines could process ICs at an astounding rate, and reach 3000 UPH at low volume ICs significantly reducing production time. This meant that ○○○ could deliver full build PCBs faster, gaining a competitive edge.

Accuracy Redefined: Precision and Quality

The switch to automated IC programming was a game-changer for ○○○ in terms of quality. The precision offered by DediProg auto handlers eliminated programming errors, resulting in consistently high-quality products and improved customer satisfaction.

Reduced Labor Costs: Efficiency Meets Savings

One of the most significant benefits for ○○○ was the substantial reduction in labor costs. The need for a large manual workforce was greatly diminished, resulting in significant cost savings.

Customization: Flexibility for Varied Peripherals

The DP1000 Series system allowed for customization in equipped different IC programmer, IC sockets, input/output peripherals, and AOI machines, ensuring versatility in their manufacturing process.

Data Integrity and Compliance: Meeting Stringent Standards

DediProg Report Engine addressed ○○○' need for data integrity and compliance. Secure management of programming data and logs ensured traceability and compliance with industry regulations.

Conclusion: ○○○'s partnership with DediProg has opened new doors to success. By applying DediProg auto handlers, they have overcome their programming challenges and achieved impressive results: streamlined their IC programming operations, enhancing efficiency, accuracy, and cost-effectiveness.

DP1000 Series Product Page

Contact us: sales@dediprog.com