【Product】Introducing DediProg's ITC Test Socket

2024-11-12

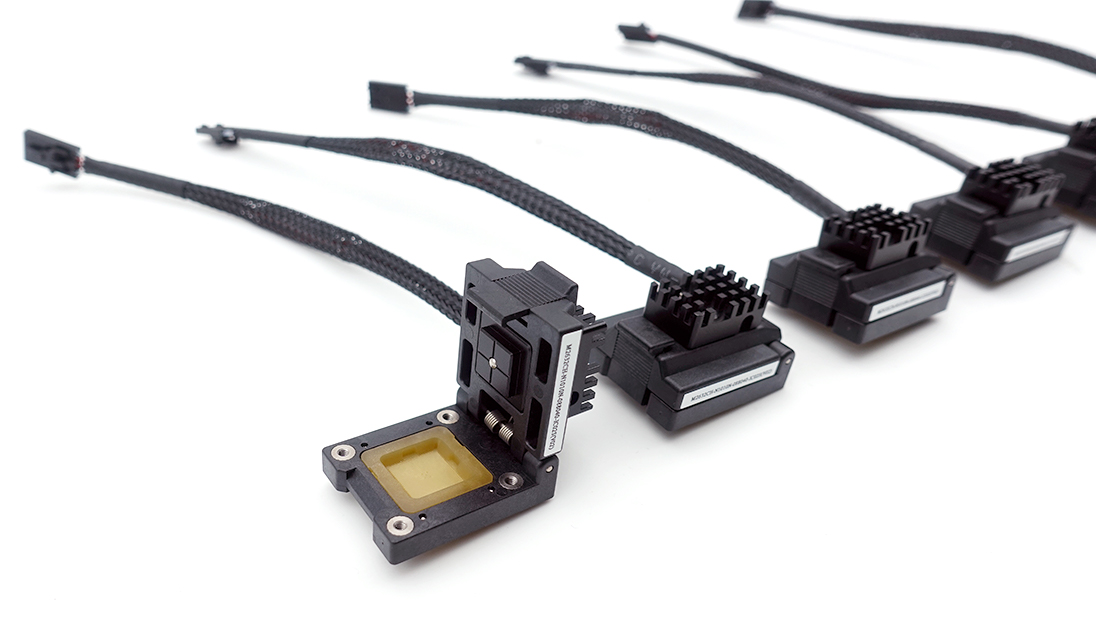

Introducing DediProg's ITC Test Socket

A Precise, Independent Temperature Control Solution for IC Burn-in Testing

DediProg introduces the ITC Test Socket, an advanced IC testing fixture designed specifically for IC burn-in tests. With its independent temperature control (ITC) feature, this socket ensures that every IC undergoes stable testing at specified temperatures, significantly enhancing testing precision, reducing cycle times, and lowering testing costs.

Challenges of Traditional IC Burn-In Testing

With the rising demand for high-performance ICs, rigorous testing is essential to ensure they meet reliability, durability, and accuracy standards. However, traditional burn-in test systems may face the following challenges:

- Inconsistent Temperature and Limited Precision

Heating multiple ICs together often requires setting temperatures higher than the target test temperature, causing temperature variations and making it difficult to maintain precise, stable conditions for each IC.

- High Energy Consumption and Longer Testing Cycle

Maintaining high temperatures over extended periods is energy-intensive and costly. Additionally, long heating and cooling cycles increase testing durations, affecting production timelines and overall efficiency.

- Space and Setup Requirements

Burn-in test systems require significant space and effective ventilation to manage heat, driving up facility costs and complicating lab setups.

Features of DediProg's ITC Test Socket

ITC (Independent Temperature Control) Test Socket |

|

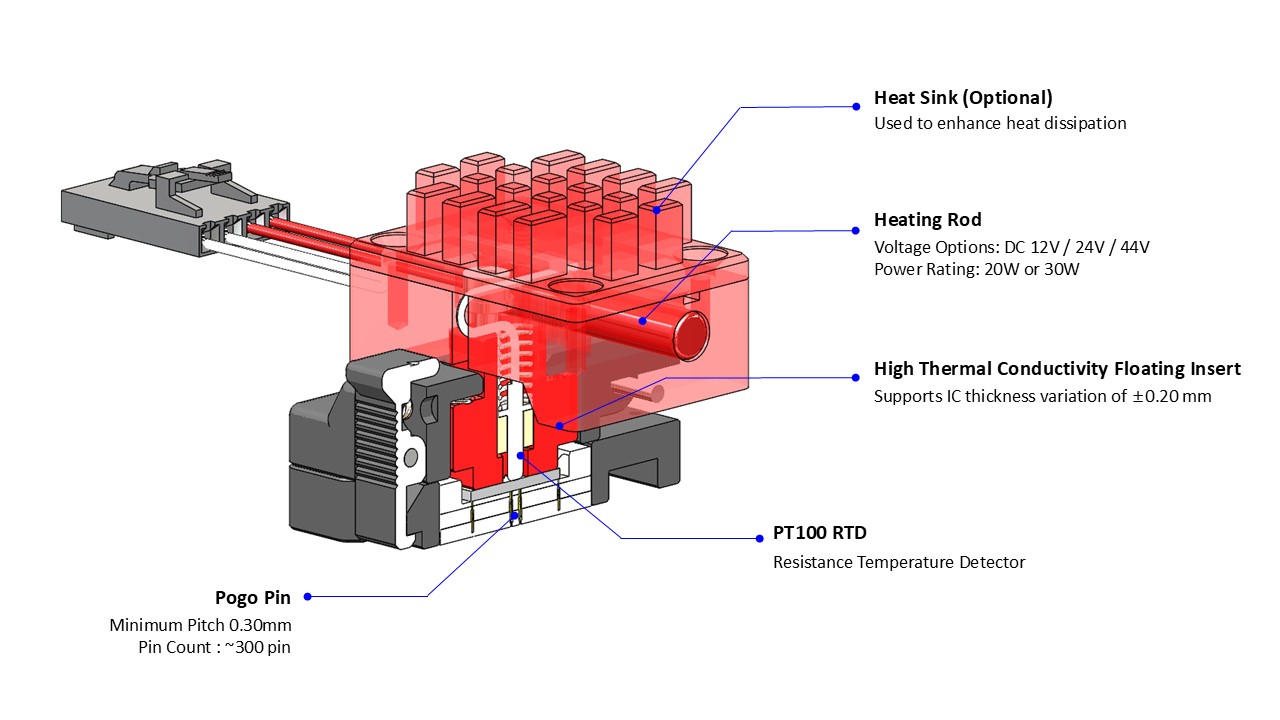

- High-Precision Temperature Control

The ITC Test Socket offers independently temperature control for each IC. Equipped with the high-precision sensors, it can temperatures within a ±0.5°C margin, adapting to diverse testing needs.

- Efficient and Durable Heating System

Equipped with durable cartridge heaters, the ITC Socket delivers efficient heat transfer and supports fast, stable heating up to 175°C.

- Flexibility to Adapt to Diverse Needs

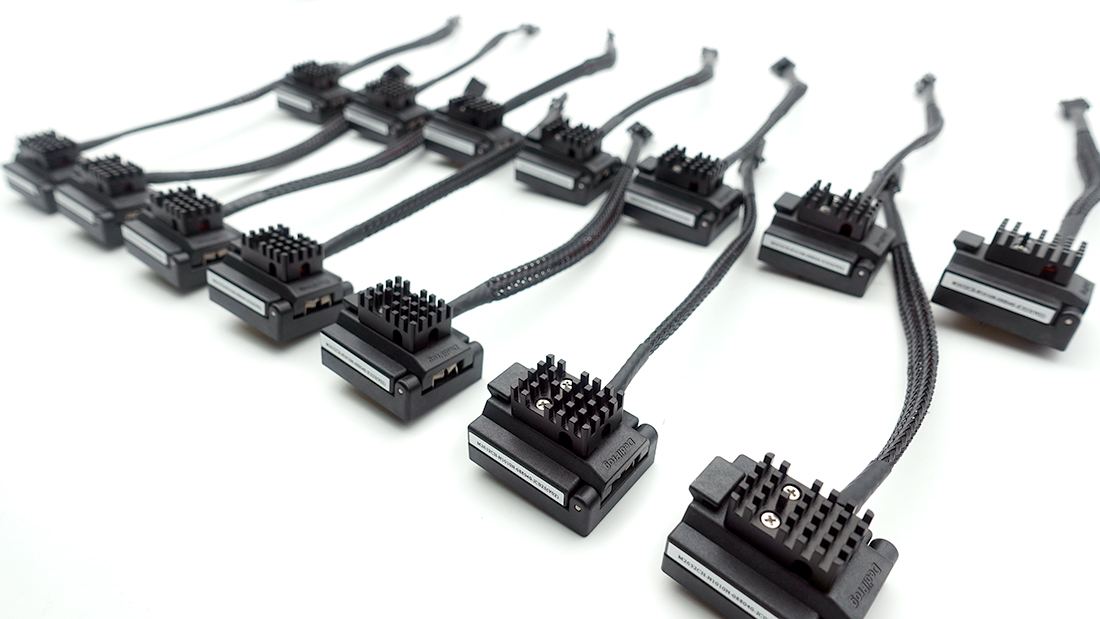

The ITC Test Socket is compatible with all IC packaging types on the market, allowing it to be utilized in various testing scenarios and conditions.

- Durable and Stable Design

Constructed from materials that withstand high temperatures and wear, the ITC Test Socket is built for long-lasting performance, enabling extended testing periods without affecting its capabilities.

Benefits of the ITC Test Socket

- Enhanced Testing Accuracy

Utilizing the ITC Test Socket enables precise temperature control, preventing uneven or inaccurate heating and enhancing the reliability of IC performance data.

- Reduced Testing Cycle Times

Optimized heating and stable temperature management reduce testing times, accelerating time-to-market for new ICs.

- Cost Efficiency

Durable construction and efficient operation help lower maintenance costs. Moreover, by minimizing errors through precise testing, the ITC Test Socket reduces returns and enhances the overall efficiency of the testing process.

Discover how the ITC Test Socket can elevate your testing precision and efficiency. Contact us for more information!

E-mail: sales@dediprog.com